Total annual cost means the sum of the costs of power maintenance and charges against the amount of capital invested. The cathodic protection system has been designed to protect the underground pipe 11 Codes and Standards All the design and installation for cathodic protection system shall be in accordance with the.

The results show that this design can not meet the grounding resistance requirement.

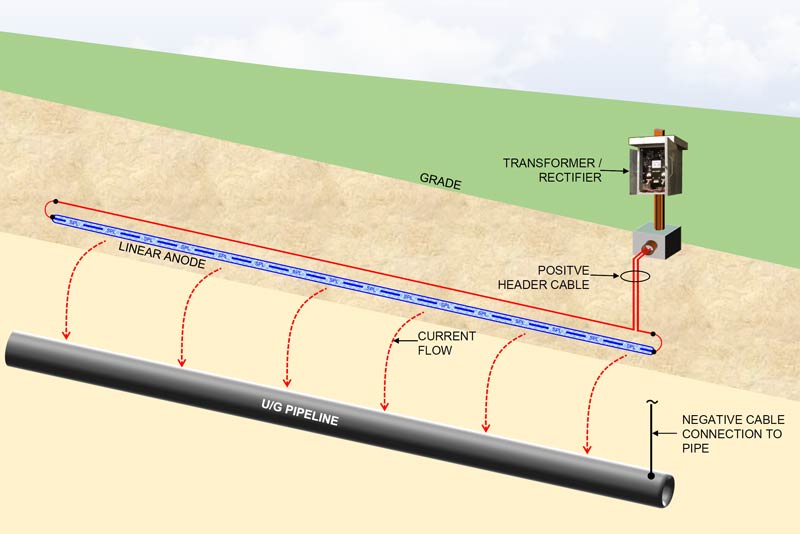

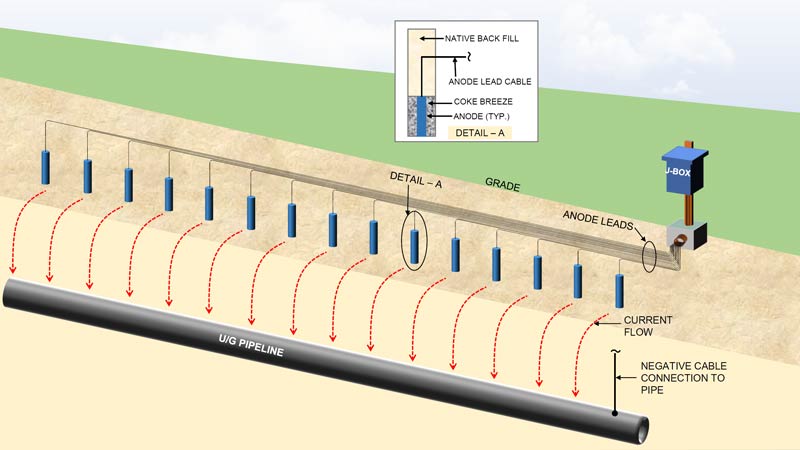

. There are three basic approaches to cathodically protect underground piping and structures using impressed current anodes. A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly. Cathodic protection system the design of anode ground bed plays very important role since the current distribution and pipe potential will be affected by anode position with respect to the.

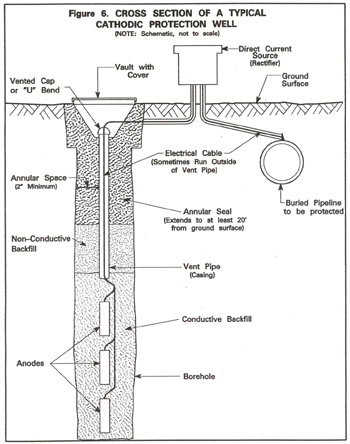

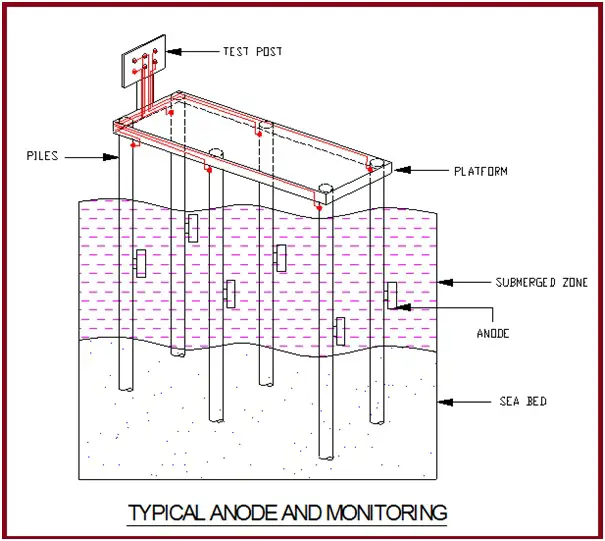

Deep Anode One method is the deep anode in which high current capacity anodes are installed from the structure in a deep hole drilled vertically 150 feet deep. Locations for the groundbed and anode system. The two types of CP systems are galvanic anode and impressed current.

Galvanic anode CP systems provide cathodic current by galvanic. Further results show that higher soil. A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly.

Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method. A groundbed cathodic protection system is a low-cost and highly effective option since various components like tanks pipes fuel pumps wirings and others need not be interrupted. 4 rows For planning and design purposes it is often.

Once the groundbed becomes operative the steel casing will be consumed. Adjustments were made to comply with customer requirements and NACE International standards. Cathodic protection system the design of anode ground bed plays very important role since the current distribution and pipe potential will be affected by anode position with.

A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly. The below factors are considered during the Design phase. Cathodic protection system the design of anode ground bed plays very important role since the current distribution and pipe potential will be affected by anode position with respect to the structure position.

CPM installed new ground beds and rectifiers energized these systems and performed necessary testing to bring them online. Search for jobs related to Cathodic protection ground bed design or hire on the worlds largest freelancing marketplace with 20m jobs. 313 Anodes Ground Bed Specification 45.

Several anodes attached together with a rope are placed inside the casing. Fine tuning of output was performed to provide optimal cathodic protection to the pipeline while minimizing power utilization. Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively.

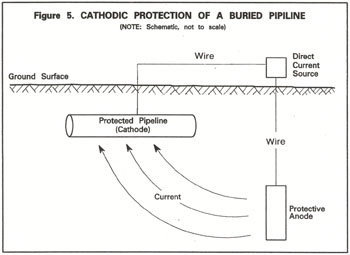

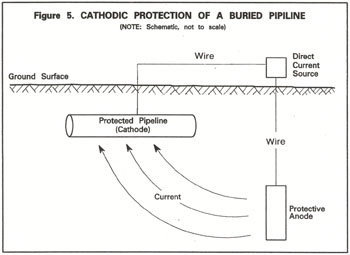

Cathodic protection is a means of reducing corrosion of a metal by artificially causing direct current to flow from external anodes through the electrolyte soil or water and onto the structure to be protected. The remaining space is then filled with carbonaceous material. CONCLUSION The key polymorphous cathodic protection upgrading design for corrosion control of steel tank bottoms in the oil and gas industry have been identified to be as follows.

A basic design incorporates the use of a steel casing to prevent the collapse of the drilled hole. Design Principles The ideal design for a cathodic protection system is the one which will provide the desired degree of protection at the minimum total annual cost over the projected life of the protected structure. Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively.

The results show that this design cannot meet the grounding resistance requirement. Electrical Isolation Insulating devices must be installed on the steel pipe so as to facilitate electrical isolation. This is analogous to lighting a football field with floodlights.

We design and install Deep Well groundbed and anode systems to distribute impressed electrical current for cathodic protection against corrosion on steel pipelines underground storage tanks and oil and gas well casings. Cathodic protection levels must be controlled so as not to damage coatings. A cathodic protection groundbed is the connection between.

Cathodic Protection Provide a level of cathodic protection for the entire length of the underground structure. Its free to sign up and bid on jobs. The current and voltage output demand to protect all of structures is defined as 154 Amperes and 40 Volts respectively.

These anodes should be buried deep in the ground a certain distance away from the structure it protects. Keywords Cathodic protection pipelines corrosion impressed current cathodic protection cathodic protection system design Introduction Cathodic Protection CP is a method that examine the design and to reduce corrosion by minimizing the optimization of cathodic protection difference in potential between anode systems applied for the. A comparison have been made.

All that is needed is a deep hole for the anodes.

Anode Installation An Overview Sciencedirect Topics

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

Cathodic Protection Well Standards

Cathodic Protection Well Standards

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

Cathodic Protection Definition Working Principles Types Design Advantages Applications Pdf What Is Piping

Cathodic Protection Definition Working Principles Types Design Advantages Applications Pdf What Is Piping

0 comments

Post a Comment